You sleep we work!

You sleep we work!

PREPRESS SERVICE

No job is too big for us to handle. We’ve handled hundreds in a day before, with a 99.9% approval rate, so not only can we handle the big jobs, but we also know what we are doing. We always strive to satisfy our clients.

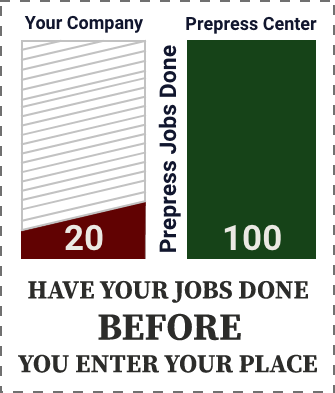

We also save you money because we will do all of your prepressing. Because outsourcing your work to us nets you sensational results, you will not have to have staff on-site to do the work. We cost less than you paying half-a-dozen salaries. In fact, using our services usually costs you roughly 50% less than the average salaries of your employees for the applicable time. Over the course of many jobs, that will add up to quite a bit. We truly enjoy helping you save on the bottom line.

The other thing that we do that not a lot of others do is start our day at midnight local time. Currently in your business, your prepress jobs filter in around 6 am, and the prepress is done by around 9 am. With us you are starting six hours before that, we can have your jobs done by the time your day starts if you’re in our time

zone. Yes, we understand that you might send us jobs from any worldwide destination. By starting our day at midnight, even if you’re many time zones away, we offer you a set timeframe for completion. We aim to be the fastest at what we do even as we handle your largest jobs.

We’ll tailor the job to your clients’ specified demographic. When we see the preflight submissions, we will double-check to ensure accuracy regarding the target demographic and make recommendations. Do they match the target demographic’s tastes? If not, then we’ll work together with you to make sure that they do.

The colors must be both bold and precise. Together with you, we’ll help your clients realize their creative potential. The proof will be bold. It’ll be professional. It’ll be just right. Remember, we have 99.9% approval, so we are confident that the proof will pass muster.

We send the job to the printers once we have your approval, and they’ll get it done. Of course, we take on worldwide jobs from anywhere, queue them up, and settle them swiftly and efficiently. Prepress shouldn’t be an undecipherable monster. We’ll help make it simple for you and your clients. By saving both you and your clients money, we aim to provide the best possible service for a lower-than-expected cost.

No job is too big for us to handle. We’ve handled hundreds in a day before, with a 99.9% approval rate, so not only can we handle the big jobs, but we also know what we are doing. We always strive to satisfy our clients.

We also save you money because we will do all of your prepressing. Because outsourcing your work to us nets you sensational results, you will not have to have staff on-site to do the work. We cost less than you paying half-a-dozen salaries. In fact, using our services usually costs you roughly 50% less than the average salaries of your employees for the applicable time. Over the course of many jobs, that will add up to quite a bit. We truly enjoy helping you save on the bottom line.

The other thing that we do that not a lot of others do is start our day at midnight local time. Currently in your business, your prepress jobs filter in around 6 am, and the prepress is done by around 9 am. With us you are starting six hours before that, we can have your jobs done by the time your day starts if you’re in our time zone. Yes, we understand that you might send us jobs from any worldwide destination. By starting our day at midnight, even if you’re many time zones away, we offer you a set timeframe for completion. We aim to be the fastest at what we do even as we handle your largest jobs.

When your clients submit the kinds of jobs that need 20 different graphics printed to showcase their wares to tens of thousands of people, then they will need world-class marketing and advertising support. People are going to see our collective work on their behalf in their mailboxes, physical or otherwise. Any kind of campaigns need to put your clients’ companies’ best foot forward. We’ll make the advertising look sublime.

We’ll tailor the job to your clients’ specified demographic. When we see the preflight submissions, we will double-check to ensure accuracy regarding the target demographic and make recommendations. Do they match the target demographic’s tastes? If not, then we’ll work together with you to make sure that they do.

The colors must be both bold and precise. Together with you, we’ll help your clients realize their creative potential. The proof will be bold. It’ll be professional. It’ll be just right. Remember, we have 99.9% approval, so we are confident that the proof will pass muster.

We send the job to the printers once we have your approval, and they’ll get it done. Of course, we take on worldwide jobs from anywhere, queue them up, and settle them swiftly and efficiently. Prepress shouldn’t be an undecipherable monster. We’ll help make it simple for you and your clients. By saving both you and your clients money, we aim to provide the best possible service for a lower-than-expected cost.

What is Prepress?

The technician must edit the graphics so that everything lines up. There should be no white border in the bleed area, for example. The first thing that the technician does is preflighting. That begins when the person checks the files to ensure that everything that should be in them is in them. Resolution, format, and color type are all part of the process. All of the fonts have to be correct too. There are margins, crop marks, and bleed. Bleed is the 3 mm space outside the borders of where the paper will be cut. That allows for slight movement of the papers in the stack and any design inconsistencies. Margins are the borders of the files. Crop marks are the actual lines that show the printer where to cut.

Think of preflighting as proofreading for the graphics. Speaking of proofreading, most technicians won’t do grammar and spell checks because the checking of all of the files’ attributes is exacting enough. It’s far better to have a separate person doing the proofreading of the writing.

Once everything is ship-shape, then it’s time for the technician to create a proof. A proof is an “almost version” of the desired finished product.

There is room for both improvements and alterations of what’s already there. Proofs usually wind up being. PDFs because that is a printer-friendly format that is also easily transmitted through email.

The proof is close enough to what’s desired that both the client and the printer can chat and then decide whether the proof fits all the criteria. If it does, then the process moves to the third stage.

Most of the time, there is no physical proof for the client to examine. In the case of a brochure, magazine, or similar publication, one the requires complex folding and/or stapling, however, it is customary to provide a physical proof by mail. The client sometimes also wants both a physical and an electronic proof for comparison’s sake.

The technician will be able to see all kinds of errors if they’re there. If the ink hue is wrong, then it’ll show up that way. If there are faults in the impression, then the technician knows that there is a problem with one of the pressure cylinders.

If something goes wrong, but the reason is at first undetectable, then the technician can use the color bars to

determine what when wrong because they’re constant while the print area is not. Some of the problems that color bars might highlight are over-emulsification, misrepresentation, and double impressions. Many of these errors would be invisible to the naked eye were it not for the constant provided by the color bars.

…use both traditional methods and newfangled methods. In much the same way that being able to draft by hand is a great thing to know before using CAD to make blueprints, knowing how to align the physical plates for printing properly is a very good way to prepare for using digital printing presses.

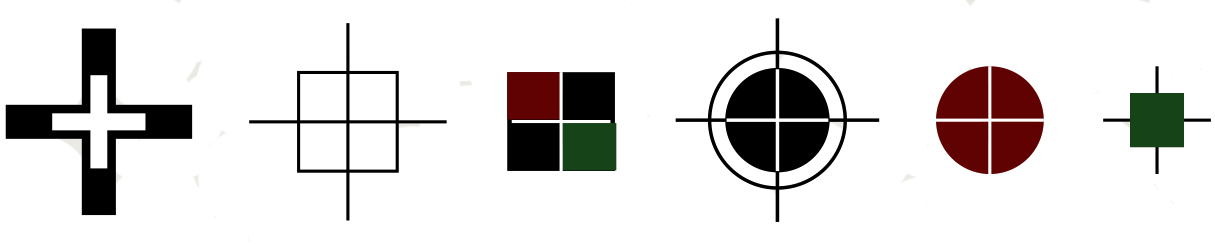

If the job is to be done on a digital printing press, then the prepress is one. The next step only concerns jobs that require physical plates. Making the plates is an exacting job. Not only do the actual plates have to line up but so do the colors, fonts, and other parts of the graphics. The printer will look at several center marks on the graphics. These marks are made up of the four basic colors: cyan, magenta, yellow, key. Those four colors make up back when they’re superimposed correctly. If the center marks are black, then the plates are correctly aligned.

The technician must edit the graphics so that everything lines up. There should be no white border in the bleed area, for example. The first thing that the technician does is preflighting. That begins when the person checks the files to ensure that everything that should be in them is in them. Resolution, format, and color type are all part of the process. All of the fonts have to be correct too. There are margins, crop marks, and bleed. Bleed is the 3 mm space outside the borders of where the paper will be cut. That allows for slight movement of the papers in the stack and any design inconsistencies. Margins are the borders of the files. Crop marks are the actual lines that show the printer where to cut.

Think of preflighting as proofreading for the graphics. Speaking of proofreading, most technicians won’t do grammar and spell checks because the checking of all of the files’ attributes is exacting enough. It’s far better to have a separate person doing the proofreading of the writing.

Once everything is ship-shape, then it’s time for the technician to create a proof. A proof is an “almost version” of the desired finished product.

There is room for both improvements and alterations of what’s already there. Proofs usually wind up being. PDFs because that is a printer-friendly format that is also easily transmitted through email.

The proof is close enough to what’s desired that both the client and the printer can chat and then decide whether the proof fits all the criteria. If it does, then the process moves to the third stage.

Most of the time, there is no physical proof for the client to examine. In the case of a brochure, magazine, or similar publication, one the requires complex

folding and/or stapling, however, it is customary to provide a physical proof by mail. The client sometimes also wants both a physical and an electronic proof for comparison’s sake.

The technician will be able to see all kinds of errors if they’re there. If the ink hue is wrong, then it’ll show up that way. If there are faults in the impression, then the technician knows that there is a problem with one of the pressure cylinders.

If something goes wrong, but the reason is at first undetectable, then the technician can use the color bars to determine what when wrong because they’re constant while the print area is not. Some of the problems that color bars might highlight are over-emulsification, misrepresentation, and double impressions. Many of these errors would be invisible to the naked eye were it not for the constant provided by the color bars.

…use both traditional methods and newfangled methods. In much the same way that being able to draft by hand is a great thing to know before using CAD to make blueprints, knowing how to align the physical plates for printing properly is a very good way to prepare for using digital printing presses.

If the job is to be done on a digital printing press, then the prepress is one. The next step only concerns jobs that require physical plates. Making the plates is an exacting job. Not only do the actual plates have to line up but so do the colors, fonts, and other parts of the graphics. The printer will look at several center marks on the graphics. These marks are made up of the four basic colors: cyan, magenta, yellow, key. Those four colors make up back when they’re superimposed correctly. If the center marks are black, then the plates are correctly aligned.

Our Process

And, you’re going to need it when you need it. That’s why we pledge to be available as early as midnight in our time zone. That way, when inspiration strikes you at odd hours, we can help you realize that inspiration! The best part is, you can go back to sleep while we work hard on your project.

By being diligent, we aim to create your graphics without error. We won’t always succeed, of course, but we’ll always provide you with the opportunity to approve our work before we submit it to the printer. We want your graphics to be stunning, visually appealing, and effective at being a hook to get people to look at your business whatever it happens to be.

Volume Processing

We’re able to handle any job, big or small. In fact, we’re capable of handling thousands of projects every day. Rest assured, though, that your project will receive the same care and attention as any other project no matter its size. Each customer is valued simply on the customer’s own merits. We like happy customers! We like satisfied customers. Nothing is ever slapdash or haphazard. Everything must be exacting and done completely to your specifications. To provide anything less would be unprofessional, and we pride ourselves on our professionalism.

Prepress involves three main steps. The first is called preflighting. We’ll start right when we receive the material you want us to use to create the graphics. We’ve got well-trained techs who will comb through your files to ensure that there aren’t any roadblocks to a successful print.

That means that we check resolution, format, and fonts to make sure they’re all correct. The CMYK color has to be right, too, so we check that. We’ll make sure that none of your overlays trap. It’s not like the old days. We’ve got powerful software as our best buddy in the process. We’ll find the traps and iron them out so that your graphics look spectacular. Most of the time, prefilighting involves converting your files to .PDF, which is a printer-friendly format.

Because we focus heavily on these aspects of your graphics, we might miss spelling, punctuation, or grammar mistakes. Therefore, it’s a good idea for you to proofread everything yourself before sending it to us.

Print Ready

These days, most jobs require only a digital printing press. If that’s the case, then this is where prepress ends and production begins. We’ll send the file to the pressing company without having to make up printing plates. If your job is one of the ones where physical copies are needed, then a lot of the time, we’ll send the physical proofs and digital files to a press that uses the old methods of creating plates and printing them mechanically.

Such presses are called “offset presses”

because the plates are offset. This allows the printer to control the process and make sure everything lines up. These plates could be made from metal, rubber, plastic, or even paper itself. They have to be able to print the images onto paper, cardboard or even metal. They might even use lasers for the engraving of the plates.

In either case, once the printer receives the material, that’s when the “rubber meets the road,” so to speak. Even the old-school presses use digital proofing software to catch any misalignments, wrong colors, or other things like that before pressing “run.” The last thing that we want to have happen is to have to redo a run.

Your Proof

The proof gives both you and the printers the chance to go over the project so that everyone can agree on what it will look like and if that satisfies your needs as the customer. When it comes to certain projects that actually do need a physical copy, such as multipage sales brochures or magazines, both you and the printers need not only to see how it looks but also how it feels. In these cases, we’ll create both proofs for you.

Trim Marks

Trim marks show the printers where to cut the paper. Bleed is the area of the graphic that extends past the trim mark. In most cases, printers will slice the paper of your project in big piles. There is a possibility of movement of the sheets of paper independently from each other within the pile when the cutting blade comes down. That will result in white edges on your printed sheets, which is undesirable. Leaving 3 mm worth of bleed past the trim marks will help keep the printed copies from having those white borders.

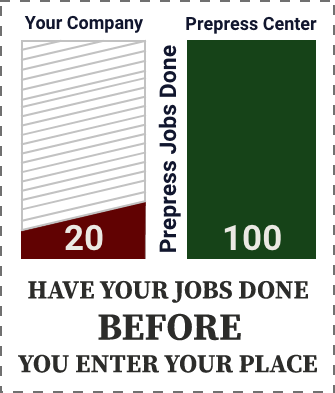

Registration Marks

Registration marks appear as circles with lines crossed at 90-degree angles superimposed upon them. Each section of the registration mark is made up of one of the four main colors: cyan, magenta, yellow, and key. The four colors together should form black, so the registration marks should appear as pure black. If they appear as any other color, then that means that the plates don’t align and need adjustment. There isn’t just one registration mark either. There are usually four or more at different parts of the plates, digital or otherwise.

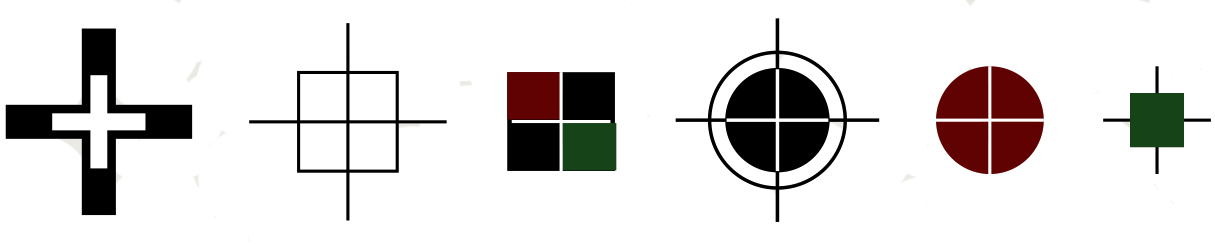

Color bars are inserted in the bleed area so that the printer, either manually or through digital assistance, can ensure and maintain quality control. The bars help the printer check color consistency throughout the graphic to be printed. Their accuracy is legendary. They can even show an error when there is an impression problem in an otherwise perfect graphic.

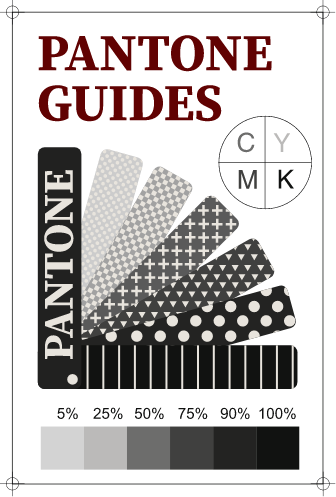

When it comes to color, CMYK is not the only option. Pantone colors are more exact and will reduce variance between print jobs on the same files. The variance using CMYK colors is roughly 5%. The tradeoff is that Pantone takes far longer because each color must be input separately instead of being formed by a combination of the four colors of CMYK. We’ll work with you to determine which of the two systems will be best for your project.

Even the most sophisticated software just uses these two age-old techniques to detect errors in both physical plates and digital graphics. The digital technology is much more accurate than even the most seasoned and skilled human eye. That’s why we check things both by hand and by digital scan.

Volume Processing

We’re able to handle any job, big or small. In fact, we’re capable of handling thousands of projects every day. Rest assured, though, that your project will receive the same care and attention as any other project no matter its size. Each customer is valued simply on the customer’s own merits. We like happy customers! We like satisfied customers. Nothing is ever slapdash or haphazard. Everything must be exacting and done completely to your specifications. To provide anything less would be unprofessional, and we pride ourselves on our professionalism.

Prepress involves three main steps. The first is called preflighting. We’ll start right when we receive the material you want us to use to create the graphics. We’ve got well-trained techs who will comb through your files to ensure that there aren’t any roadblocks to a successful print.

That means that we check resolution, format, and fonts to make sure they’re all correct. The CMYK color has to be right, too, so we check that. We’ll make sure that none of your overlays trap. It’s not like the old days. We’ve got powerful software as our best buddy in the process. We’ll find the traps and iron them out so that your graphics look spectacular. Most of the time, prefilighting involves converting your files to .PDF, which is a printer-friendly format.

Because we focus heavily on these aspects of your graphics, we might miss spelling, punctuation, or grammar mistakes. Therefore, it’s a good idea for you to proofread everything yourself before sending it to us.

Print Ready

These days, most jobs require only a digital printing press. If that’s the case, then this is where prepress ends and production begins. We’ll send the file to the pressing company without having to make up printing plates. If your job is one of the ones where physical copies are needed, then a lot of the time, we’ll send the physical proofs and digital files to a press that uses the old methods of creating plates and printing them mechanically.

Such presses are called “offset presses” because the plates are offset. This allows the printer to control the process and make sure everything lines up. These plates could be made from metal, rubber, plastic, or even paper itself. They have to be able to print the images onto paper, cardboard or even metal. They might even use lasers for the engraving of the plates.

In either case, once the printer receives the material, that’s when the “rubber meets the road,” so to speak. Even the old-school presses use digital proofing software to catch any misalignments, wrong colors, or other things like that before pressing “run.” The last thing that we want to have happen is to have to redo a run.

Your Proof

The proof gives both you and the printers the chance to go over the project so that everyone can agree on what it will look like and if that satisfies your needs as the customer. When it comes to certain projects that actually do need a physical copy, such as multipage sales brochures or magazines, both you and the printers need not only to see how it looks but also how it feels. In these cases, we’ll create both proofs for you.

Trim Marks

Trim marks show the printers where to cut the paper. Bleed is the area of the graphic that extends past the trim mark. In most cases, printers will slice the paper of your project in big piles. There is a possibility of movement of the sheets of paper independently from each other within the pile when the cutting blade comes down. That will result in white edges on your printed sheets, which is undesirable. Leaving 3 mm worth of bleed past the trim marks will help keep the printed copies from having those white borders.

Registration Marks

Registration marks appear as circles with lines crossed at 90-degree angles superimposed upon them. Each section of the registration mark is made up of one of the four main colors: cyan, magenta, yellow, and key. The four colors together should form black, so the registration marks should appear as pure black. If they appear as any other color, then that means that the plates don’t align and need adjustment. There isn’t just one registration mark either. There are usually four or more at different parts of the plates, digital or otherwise.

Color bars are inserted in the bleed area so that the printer, either manually or through digital assistance, can ensure and maintain quality control. The bars help the printer check color consistency throughout the graphic to be printed. Their accuracy is legendary. They can even show an error when there is an impression problem in an otherwise perfect graphic.

When it comes to color, CMYK is not the only option. Pantone colors are more exact and will reduce variance between print jobs on the same files. The variance using CMYK colors is roughly 5%. The tradeoff is that Pantone takes far longer because each color must be input separately instead of being formed by a combination of the four colors of CMYK. We’ll work with you to determine which of the two systems will be best for your project.

Even the most sophisticated software just uses these two age-old techniques to detect errors in both physical plates and digital graphics. The digital technology is much more accurate than even the most seasoned and skilled human eye. That’s why we check things both by hand and by digital scan.

Support

We are dedicated to delivering world-class service across every aspect of our work, ensuring that you can rely on us to address any challenge you encounter—whenever it arises. Our commitment extends beyond standard support; we are fully prepared to accommodate last-minute adjustments to your project with efficiency and precision. Should you require a sudden modification, we will gladly implement the change, working diligently to ensure a seamless transition without any negative impact on the outcome.

Contact the prepress center

Inquiries#and%Correspondence:

Telephone:;+1^415@715[1515$

Facsimile:~+1*415}466\8333&

Telex: 310151 PATROLLC SFO USA